The Manufacturing Intelligence Shift: How o4-mini Brings Reasoning AI to Production Floors

5 December, 2025

Key Takeaways:

- Manufacturing competitiveness now depends on AI-native infrastructure, where reasoning models like o4-mini elevate operations from sample-based oversight to continuous, system-wide intelligence.

- The shift from traditional AI to reasoning-driven automation marks a structural upgrade: enterprises that deploy o4-mini move from reactive quality control to predictive, self-correcting production environments.

- The economics of o4-mini redefine what’s operationally possible. When per-unit analysis becomes affordable, high-throughput manufacturing gains capabilities once reserved for high-margin industries.

- Deploying reasoning models demands enterprise-grade data foundations, edge-to-cloud integration, and disciplined validation loops that translate AI outputs into trusted operational decisions.

- The manufacturers that win this decade are the ones treating AI as production infrastructure; instrumented lines, multimodal intelligence, and compounding workflows that learn, adapt, and improve across every shift.

For years, manufacturers have faced a structural constraint: deploy AI on only a small percentage of units and accept blind spots, or expand coverage and absorb compute costs that erode margins. In high-throughput environments where a single defect can ripple through downstream operations, neither path scaled, which is why industrial AI stayed stuck in pilots and was never fully operationalized.

On April 16, 2025, OpenAI released o4-mini (OpenAI, 2025). For the first time, a reasoning model that combines image analysis, autonomous problem-solving, and logical inference became affordable enough to support continuous deployment across production units.

The question is no longer whether AI can help. It's how fast you can integrate it into the workflows that already exist on your factory floor.

This article examines what o4-mini enables for industrial operations, why its architecture represents a strategic shift for manufacturing AI, and what it signals about the infrastructure requirements for AI-native production environments.

From o1 to o4-mini: What Made Reasoning Models Viable for Manufacturing?

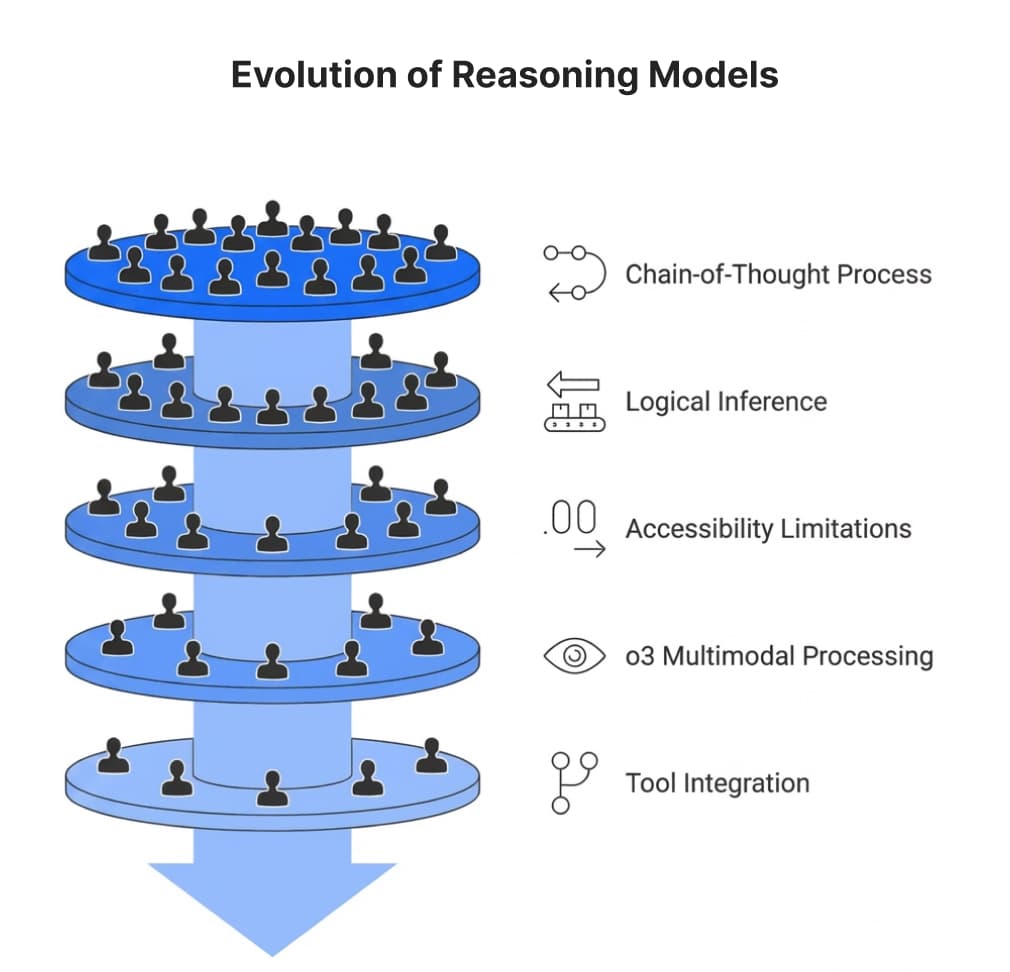

The o1 Foundation

In late 2024, OpenAI introduced o1, the first model trained explicitly for reasoning. Unlike traditional language models that generated responses through pattern matching, o1 employed an internal chain-of-thought process, allowing it to decompose complex problems, evaluate multiple solution paths, and self-correct before producing outputs (OpenAI, 2024)

For manufacturing applications requiring logical inference, root cause analysis, process optimization, and compliance verification. This represented a fundamental advance.

The limitation was accessibility. o1 operated solely on text and lacked the tool integration necessary for autonomous workflows. It proved reasoning models worked but remained too expensive for high-volume production use.

The o3 Constraint

With the general availability of o3 on April 16, 2025, OpenAI demonstrated what reasoning models could achieve at scale (OpenAI, 2025).

o3 introduced multimodal processing, integrating visual and textual inputs, and full tool integration, enabling autonomous web search, Python execution, file analysis, and memory.

Despite its capabilities, its initial pricing structure of $10 per million input tokens and $40 per million output tokens (TechTarget, 2025) restricted its use to high-value decision points: engineering design validation, strategic supply chain analysis, and high-stakes quality audits.

While o3 demonstrated the upper bound of reasoning capability, its cost limited deployment at production scale.

What o4-mini Brings to Manufacturing Operations

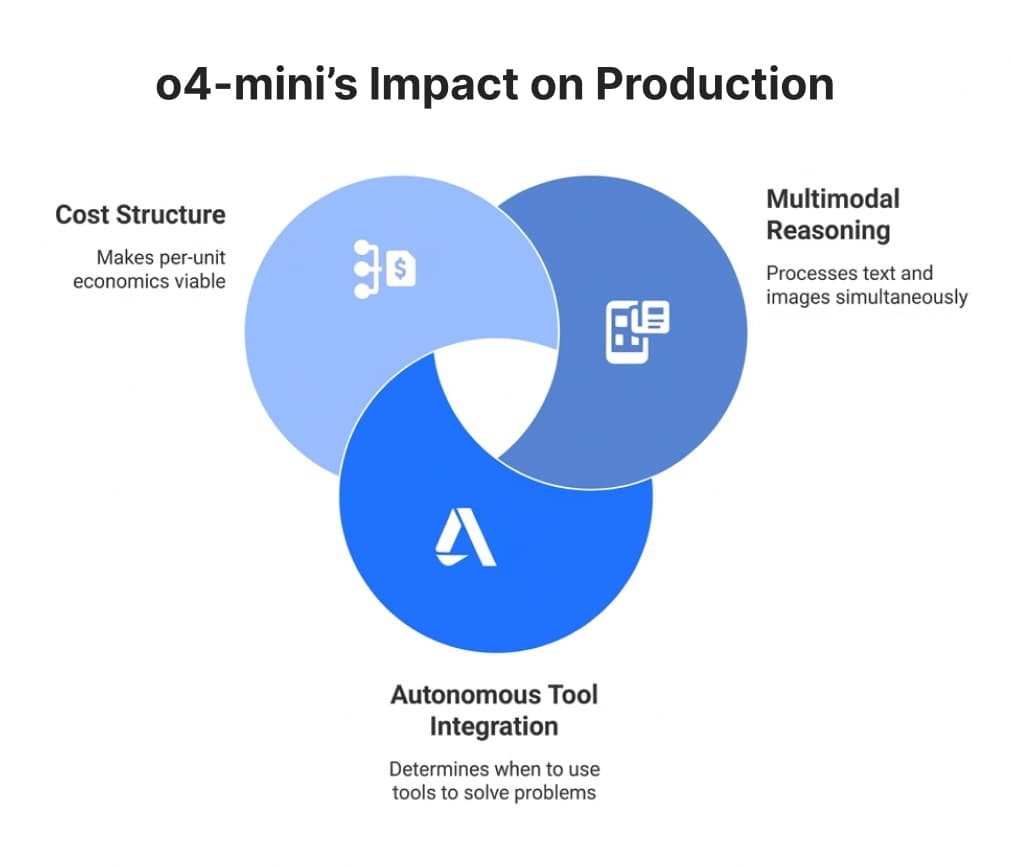

o4-mini, released concurrently with o3 on April 16, 2025 (OpenAI, 2025), addressed the deployment gap directly. It delivers three capabilities that shift AI from pilot programs to production infrastructure: multimodal reasoning, autonomous tool use, and deployable economics.

Multimodal Reasoning

The model processes text and images simultaneously within a single reasoning chain.

This means visual inspection results can inform documentation queries, specification compliance checks can incorporate product imagery, and failure mode analysis can synthesize sensor data with equipment manuals, all without brittle integration pipelines.

Autonomous Tool Integration

o4-mini autonomously determines when to search databases, execute statistical calculations, or retrieve technical documentation within the context of solving a specific problem.

Operations teams define problem, and the model determines the required steps. Thereby, removing the need to script workflow branches manually.

o4-mini’s core advantage is its pricing model, which enables deployment on every unit. For operations where inspection volumes measure in thousands daily, this represented the difference between sampling-based quality control and census-based assurance.

Cost Structure

At $1.10 per million input tokens and $4.40 per million output tokens, a 10x reduction from o3's price point, o4-mini crosses the threshold where per-unit economics become viable for continuous monitoring applications. (TechTarget, 2025)

For high-volume production lines, the cost difference between o4-mini and o3 determines whether AI-assisted inspection remains a pilot or becomes standard procedure. Specific ROI will vary by workload; enterprises should pilot representative production volumes and measure outcomes before scaling.

Manufacturing Transformation: High-Value AI Use Cases Enabled by o4-mini

Supply Chain Optimization

o4-mini's tool integration enables autonomous analysis that searches current market pricing, analyzes inventory databases, executes optimization calculations, and presents recommendations with full reasoning chains. For enterprises managing thousands of SKUs with dynamic pricing, this represents meaningful improvement in decision quality at scale.

Visual Quality Inspection

In manufacturing quality assurance, most plants rely on sampling-based QA, analyzing only a small percentage of units.

o4-mini's multimodal reasoning enables census-based inspection where each unit is photographed, paired with specification documentation, and analyzed for conformance with full audit trails explaining rejection decisions.

Predictive Maintenance

Equipment failures carry cascading costs, with manufacturing facilities experiencing an average of 326 hours of unplanned downtime annually (Siemens, 2024). o4-mini ingests sensor telemetry to identify anomalous trends, searches maintenance databases for historical patterns, and generates recommendations with supporting reasoning before failures occur.

Process Documentation

Production technicians can query o4-mini about procedure compliance, equipment operation limits, or material compatibility and receive answers grounded in specific document sections with citations.

The reasoning capability synthesizes information across multiple documents autonomously, shifting documentation from passive reference material to active operational support.

Deployment Limitations

o4-mini is subject to standard limitations of reasoning models. Smaller models hallucinate more frequently than their larger counterparts (OpenAI, 2025), and visual analysis may misclassify edge cases or vary across similar defect types.

Manufacturing deployments requiring regulatory compliance should implement validation workflows where predictions undergo verification before influencing physical processes. Predictions should be validated experimentally where required for safety-critical decisions

The Strategic Shift: Intelligence as Infrastructure

Forward-looking manufacturing executives are treating reasoning models as core operational infrastructure embedded into quality, maintenance, and supply chain workflows

A single o4-mini deployment handles quality inspection, maintenance analysis, and procurement decisions across shifts, reducing complexity while enabling insights from one workflow to inform another without manual integration.

Enterprises that instrument production environments, integrate o4-mini into operational systems, and measure outcomes will develop compounding advantages. Inspection images, defect logs, and sensor traces become proprietary data assets that strengthen future models.

Conclusion: The Deployment Advantage

o4-mini signals a broader industry shift. By making reasoning capabilities economically viable at production scale, manufacturers can integrate AI directly into real production cycles rather than isolated pilots.

Manufacturers that validate o4-mini on actual production data, measure quantifiable outcomes, and expand proven applications will build sustainable competitive leads.

For teams navigating the transition from prototype to deployment, applied-AI engineering partners such as CodeNinja accelerate implementation. We architect integration systems, configure reasoning models for industrial workflows, and deploy multimodal capabilities into auditable production environments.

Manufacturing competitiveness now hinges on deployment execution, rather than model access. o4-mini makes unit-level AI deployment financially feasible for enterprises committed to building internal capability through disciplined integration.

Partner with CodeNinja to pilot o4-mini with your production data. No vendor lock-in, full model access, and measurable ROI before you scale. Contact Us

Bibliography

Kerner, Sean Michael. "OpenAI o3 and o4 Explained: Everything You Need to Know." TechTarget. Accessed December 1, 2025. https://www.techtarget.com/whatis/feature/OpenAI-o3-explained-Everything-you-need-to-know.

OpenAI. 2025. "Introducing OpenAI o3 and o4-mini." OpenAI Blog. April 16, 2025. https://openai.com/index/introducing-o3-and-o4-mini/.

OpenAI. 2024. "OpenAI o1 System Card." OpenAI. Accessed December 1, 2025. https://openai.com/index/openai-o1-system-card/.

OpenAI. 2025. "OpenAI o3 and o4-mini System Card." OpenAI. April 16, 2025. https://cdn.openai.com/pdf/2221c875-02dc-4789-800b-e7758f3722c1/o3-and-o4-mini-system-card.pdf.

Siemens. 2024. "The True Cost of Downtime 2024." Siemens Digital Industries Software. Accessed December 1, 2025. https://assets.new.siemens.com/siemens/assets/api/uuid:1b43afb5-2d07-47f7-9eb7-893fe7d0bc59/TCOD-2024_original.pdf.

FAQs

Q1 How does o4-mini improve manufacturing throughput without replacing the existing MES infrastructure?

o4-mini layers AI reasoning over current MES systems, providing real-time recommendations, alerts, and automated checks without altering MES structure. This accelerates throughput and modernizes production digitally.

Q2 What internal data foundations are required to operationalize AI use cases like visual inspection at full scale?

Manufacturers need standardized image capture, sensor telemetry, and traceability metadata. Standardized images, timestamps, part IDs, and equipment readings ensure o4-mini can reason reliably and reduce failure points during scale-up.

Q3 How does o4-mini support regulatory compliance in FDA and ISO-driven environments?

The model provides auditable reasoning chains, documented inspection rationale, and traceable version control, enabling digital proof of compliance that aligns with industry governance requirements.

Q4 What differentiates o4-mini deployments executed by CodeNinja from generic AI integrations?

CodeNinja builds AI as intelligent infrastructure. Configuring multimodal reasoning into real production systems, enforcing validation loops, and ensuring compounding learning across all operational domains.